The extensive toolbox of methods of the TRIZ method enables the hair-fine fragmentation of problems. The more precisely a problem is dissected, the more efficiently the possibilities of breaking out of previous thought patterns and developing new ideas for details take hold, thus advancing to previously unknown solutions.

This process can be very laborious and lengthy – but it leads to rewarding, compelling results. These TRIZ application examples present you with some concrete implementations that impressively demonstrate this innovation path – both in initial simpler and complex development environments.

Complex TRIZ application example: Development of the galaxy drive with TRIZ

The Galaxie drive system with hollow shaft has a completely new type of gear unit with dynamized individual teeth that achieves much more power with a more compact form for high-performance mechanical engineering and handling technology through hydrodynamic surface contact. The new gearbox was a major leap forward in development for Wittenstein AG in 2015. The development had taken several years. The decisive step was taken when Dipl.-Ing. Thomas Bayer’s team became aware of the importance of “local quality” through TRIZ: “Then it was clear that we needed real surface contact in the gear teeth and that this could only be achieved by segmenting the gear into individual teeth.”

The TRIZ method helped break the deadlock of familiar concepts and thought patterns by breaking down the problems into increasingly abstract units down to segmentation, equipotential, dynamization, and local quality. Read more about this TRIZ application example in a technical article by Dipl.-Ing. Thomas Bayer, Head of Innovation Lab, Wittenstein AG.:

The film is a recording of the presentation by Thomas Bayer (Head of Innovation Lab, WITTENSTEIN AG) at the German TRIZ User Day 2016. “One of the best presentations I’ve had the pleasure of listening to on the subject of TRIZ in development, with a sensational product as the result of this TRIZ project. The lecture should be a must for every German-speaking TRIZ user,” describes Dr. Robert Adunka.

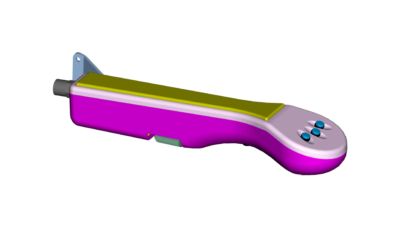

Redesign of the SIEMENS Mobility streetcar driver seat armrest using the TRIZ innovation methodology.

In this project work from 2008 by Phillip Schrieverhoff, solution concepts for a driver’s seat armrest in a streetcar were developed using particularly practical TRIZ methods of Level 1 to illustrate the interaction of the tools and the application of the individual instruments. In addition to the work as a PDF file, the ZIP file also contains further information such as an innovation checklist for the driver’s armrest and various concepts for its adjustability.

In the following TRIZ application example for TRIZ, the method acts as a mediator between marketing and engineers:

The presentation is held in German, the slides shown are in English.

A key switch for Siemens, modified using TRIZ methods

The goal at Siemens was to make the design smaller as well as simplify assembly to reduce costs. At a TRIZ workshop, functional analysis and trimming, resource listing, feature transfer, and application of the 40 innovative principles resulted in a total of 39 new solution proposals. These suggestions were reviewed with the manufacturer of the locking cylinder and resulted in a new improved model within two weeks.

The solution finally applied reduced production costs by a third, was noticeably smaller than the original and also offered a new feature: in the “0” position, the key is automatically ejected, so this security-relevant key cannot be forgotten in the lock.

Here you can see a summary of the changes:

The final concept is based on the principle that a telescopic rod replaces the plunger in the “23 mm stroke plunger” concept to shorten stroke – an application of the principle of nesting, # 7: Matryoshka. A spring pushes the telescopic rod apart.

Best Friends by MAM

One TRIZ application example at MAM was the manufacturing process for the “MAM Friends” grasping toys. TRIZ was used to simplify the complex and time-consuming manufacturing process and reduce the reject rate. In particular, the methods RCA+ (Root Conflict Analysis), FA (Functional Analysis) and trimming were applied. Eight components of a specific work step were trimmed in the manufacturing process, partly with the help of patent inspiration.

Optimum backlight diffusion: project report

The problem of illuminating the edge of the stele at night without a dark edge was solved with the help of various procedures and TRIZ methods such as innovation checklist, functional analysis, root conflict analysis, contradiction matrix, separation principles and 4-field matrix. This work is a successful practical work, it does not have the character of a thesis. Here you can download the abstract as a free eBook.

Galaxie-Konstrukteur

Galaxie-Konstrukteur

PatentInspiration

PatentInspiration